- Home

- About Us

-

Training

▼

- Graphics Design

- 3D Animation & VFX

- UI & UX Design

- Interior Design | Architecture

- Civil Engineering

- Mechanical Engineering

- CNC & CAM Engineering

- Mould Design Engineering

- Art CAM Design Engineering

- Electrical Engineering

- Automobile Electric Automation Engineering

- Computer Aided Design Course Content

- Computer Aided Engineering

- Aeronautical Engineering

- Advance Program In MEP

- Advance Program In Composition and Editing

- 3D Scan Reverse Engineering In Product Design

- Gallary ▼

- Blog

- Inquiry

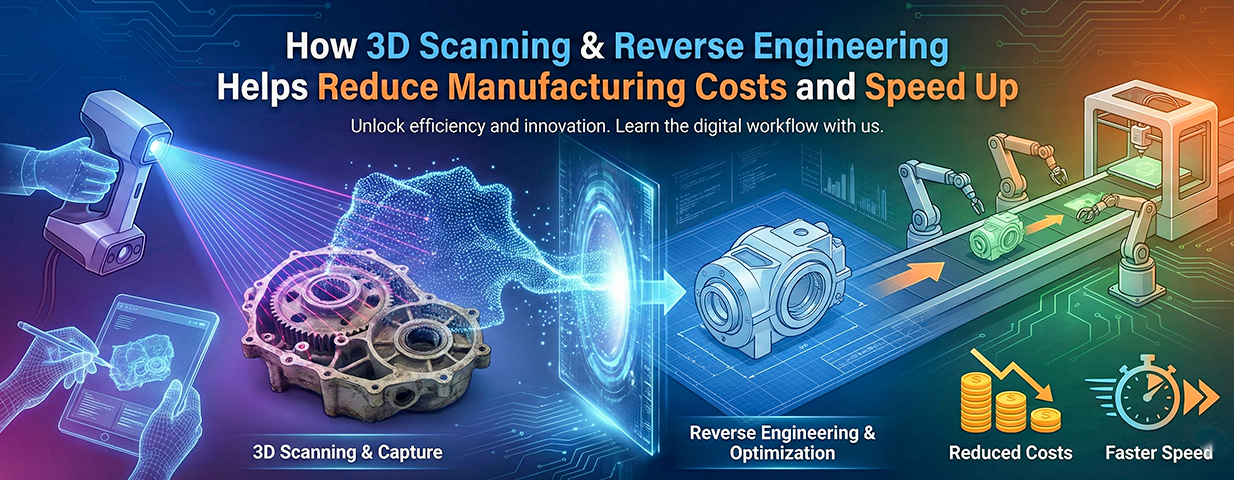

How 3D Scanning & Reverse Engineering Help Reduce Manufacturing Costs and Speed Up Production

In today’s competitive manufacturing environment, companies face constant pressure to reduce production costs, enhance accuracy, and shorten product development cycles. Traditional manufacturing methods often rely on manual measurements, repeated prototyping, and trial-and-error approaches—leading to higher costs and longer lead times.

This is where 3D scanning and reverse engineering play a transformative role. By digitizing physical components and converting them into accurate CAD models, manufacturers can significantly reduce manufacturing costs and speed up production while improving product quality. These technologies are now core modules taught at leading engineering design institutes in Ahmedabad to prepare industry-ready professionals.

What Is 3D Scanning and Reverse Engineering?

3D scanning is a technology that captures the exact geometry of a physical object using laser or structured-light scanners. The result is a highly accurate digital representation known as a point cloud or mesh.

Reverse engineering uses this scanned data to recreate precise CAD models, especially when original design drawings or data are unavailable. Together, these technologies form the foundation of modern digital manufacturing processes, widely adopted by industries and taught at reputed engineering institutes in Ahmedabad.

How 3D Scanning Reduces Manufacturing Costs

1. Eliminates Manual Measurement Errors

Manual measurements are time-consuming and prone to inaccuracies. 3D scanning for manufacturing captures millions of data points with high precision, eliminating errors that often lead to costly rework.

This level of accuracy directly supports manufacturing cost reduction using 3D scanning, making it a preferred solution in high-precision industries.

2. Minimizes Material Waste

Accurate digital models help manufacturers plan material usage efficiently. With precise geometry, parts are produced right the first time—reducing scrap, rejects, and wasted raw materials.

3. Reduces Prototyping Expenses

By validating designs digitally, manufacturers reduce the need for multiple physical prototypes. Virtual inspection and simulation allow engineers to detect issues early, saving both time and money.

4. Improves Quality Control

3D scanning enables part-to-CAD comparison, helping detect deviations before mass production. Early defect detection prevents recalls and improves overall product reliability.

How Reverse Engineering Speeds Up Production

1. Faster Product Development

Reverse engineering for faster product development allows engineers to recreate existing components quickly instead of designing from scratch. This drastically shortens design cycles and accelerates time-to-market.

2. Manufacturing Obsolete Parts

One major advantage is reverse engineering for obsolete parts manufacturing. When original drawings or suppliers are unavailable, scanned data enables rapid reproduction—reducing machine downtime.

3. Easy Design Optimization

Reverse-engineered CAD models allow quick design modifications to improve performance, reduce weight, or adapt parts for new manufacturing methods.

4. Seamless CNC & CAM Integration

CAD models generated through reverse engineering integrate directly with CAM and CNC systems, speeding up toolpath generation and production workflows.

Scan to CAD Workflow Explained

The scan to CAD workflow is central to digital manufacturing efficiency:

- 3D Scanning – Capture physical geometry

- Point Cloud Processing – Clean and align scan data

- CAD Modeling – Create parametric CAD models

- Design Validation – Inspection and optimization

- Manufacturing Integration – CNC, CAM, or 3D printing

This workflow clearly demonstrates how scan to CAD speeds up production by eliminating repetitive manual design steps—skills commonly emphasized in practical training at an engineering design institute in Ahmedabad.

Industries Using 3D Scanning & Reverse Engineering

The benefits of 3D scanning in the manufacturing industry are evident across multiple sectors:

- Automotive and EV manufacturing

- Aerospace and aviation

- Industrial machinery and tooling

- Medical devices

- Heavy engineering and casting

- Consumer product manufacturing

These industries rely heavily on reverse engineering in manufacturing to stay competitive and cost-efficient.

Role of 3D Scanning in Digital Manufacturing

3D scanning and reverse engineering are key technologies supporting Industry 4.0. They enable digital twins, predictive maintenance, and data-driven decision-making.

By creating accurate digital models of physical assets, manufacturers improve process efficiency and product consistency—skills now considered essential by modern engineering institutes in Ahmedabad.

Why Learn 3D Scanning & Reverse Engineering in 2025

As manufacturing becomes more digital, demand for skilled professionals in 3D scanning and reverse engineering is increasing rapidly.

Career Opportunities Include

- Reverse Engineering Engineer

- 3D Scanning Specialist

- CAD Design Engineer

- Manufacturing Process Engineer

- Quality Inspection Engineer

Professionals trained in scan-to-CAD workflow and digital manufacturing enjoy strong career growth, especially when trained through a recognized engineering design institute in Ahmedabad.

Conclusion

Understanding how 3D scanning reduces manufacturing costs and how reverse engineering speeds up production is essential for modern manufacturing success. These technologies eliminate errors, reduce waste, accelerate design cycles, and enable faster production—all while improving product quality.

Manufacturers that adopt 3D scanning and reverse engineering gain a strong competitive advantage, and engineers trained through a trusted engineering institute in Ahmedabad are well-positioned to lead the future of digital manufacturing.