- Home

- About Us

-

Training

▼

- Graphics Design

- 3D Animation & VFX

- UI & UX Design

- Interior Design | Architecture

- Civil Engineering

- Mechanical Engineering

- CNC & CAM Engineering

- Mould Design Engineering

- Art CAM Design Engineering

- Electrical Engineering

- Automobile Electric Automation Engineering

- Computer Aided Design Course Content

- Computer Aided Engineering

- Aeronautical Engineering

- Advance Program In MEP

- Advance Program In Composition and Editing

- 3D Scan Reverse Engineering In Product Design

- Gallary ▼

- Blog

- Inquiry

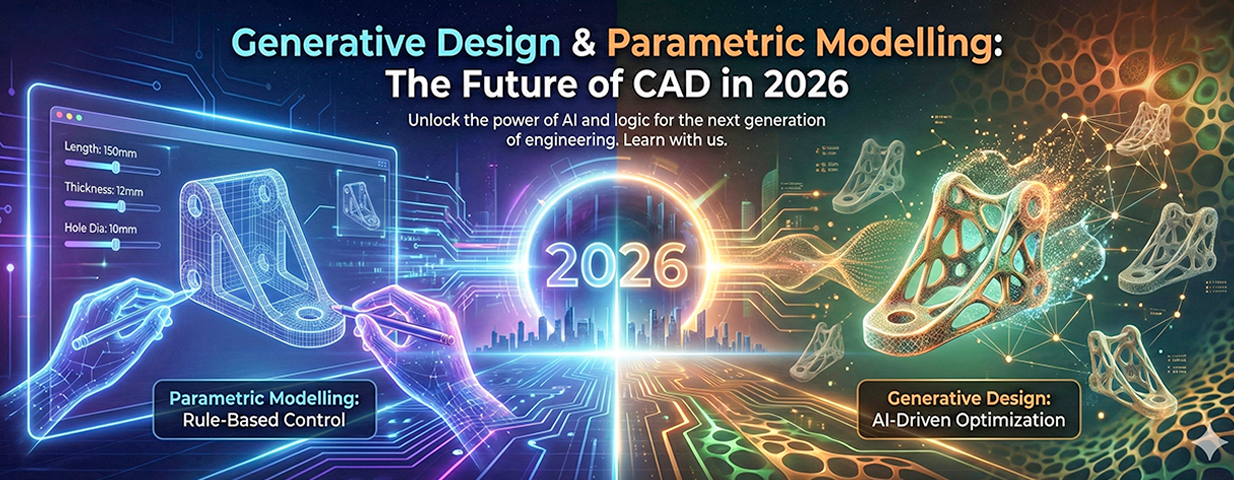

Generative Design & Parametric Modelling: The Future of CAD, CAE & Mechanical Design in 2026

Engineering design is undergoing a major transformation. Traditional CAD tools that once focused only on geometry are evolving into intelligent systems powered by AI, generative design, and parametric modelling. In 2026, modern CAD design software for mechanical engineers is no longer just a drafting tool—it has become a powerful decision-making platform integrated with CAE simulation and advanced mechanical design workflows.

This shift is redefining how engineers approach mechanical product design using CAD, optimizing performance, and significantly reducing development time.

What Is Generative Design in CAD?

Generative design in CAD uses artificial intelligence and advanced algorithms to automatically generate multiple design options based on defined constraints such as weight, material, strength, cost, and manufacturing process.

Instead of manually creating and testing designs, engineers input design goals and allow AI-powered CAD design software to explore thousands of optimized solutions—many of which would be impossible to design manually.

Why Generative Design Matters for Mechanical Engineering

- Creates lightweight yet strong components

- Reduces material usage and manufacturing cost

- Accelerates product development cycles

- Improves design innovation

- Supports mechanical CAD design for manufacturing

In 2026, generative design is widely adopted across aerospace, automotive, industrial machinery, and advanced mechanical design engineering software environments.

Understanding Parametric Modelling in Modern CAD

Parametric CAD modeling allows designers to control geometry through parameters, constraints, and relationships. When one parameter changes, the entire model updates automatically—saving time and eliminating errors.

In parametric CAD design for mechanical parts, every dimension and feature remains linked, making design modifications faster, more accurate, and scalable.

Key Benefits of Parametric Modelling

- Faster design revisions

- Improved design consistency

- Scalable product families

- Enhanced collaboration

- Strong compatibility with CAD to CAE integrated workflow

Parametric modelling has become essential in advanced CAD design techniques 2026, especially for complex mechanical assemblies.

Generative Design vs Parametric Modelling

| Feature | Generative Design | Parametric Modelling |

| Approach | AI-driven optimization | Rule-based design |

| Designer Control | Indirect | Direct |

| Best Use | Innovation & optimization | Design accuracy |

| Integration | CAD + CAE | CAD workflows |

| Role in Mechanical Design | Performance-driven | Structure-driven |

Together, they form the foundation of next-generation CAD software.

AI in CAD Design: Transforming Engineering Workflows

AI in CAD design is bridging the gap between modeling and analysis. Modern platforms now include built-in intelligence that can:

- Predict design failures

- Suggest design improvements

- Optimize geometry automatically

- Reduce human errors

This evolution has led to the rise of AI-driven CAE analysis software, where simulations run alongside CAD modeling instead of being treated as a separate process.

CAD to CAE Integrated Workflow: The New Industry Standard

One of the biggest changes in mechanical design with CAD and CAE integration is real-time simulation. Engineers now validate designs during modeling—not after.

Using CAE simulation for mechanical design, professionals can analyze:

- Structural strength

- Thermal performance

- Fatigue life

- Vibration behavior

This CAD to CAE integrated workflow improves accuracy, reduces rework, and significantly speeds up product validation.

Advanced CAD Techniques Shaping Mechanical Design in 2026

To remain competitive, engineers must master advanced mechanical design techniques that go beyond basic drafting.

Key Advanced CAD Design Techniques

- Topology optimization

- Design for additive manufacturing (DfAM)

- Multi-body parametric modeling

- Digital twin development

- CAD-driven CAE simulation

These techniques are essential in modern mechanical design engineering software and are widely taught in industry-focused training programs.

Next-Generation CAD Software: What’s Changing in 2026?

Next-generation CAD software is becoming smarter, faster, and more collaborative. Key advancements include:

- Cloud-based design collaboration

- AI-powered generative engines

- Embedded CAE analysis tools for product validation

- Parametric and rule-based automation

- Full Industry 4.0 compatibility

These platforms allow engineers to focus more on innovation and less on repetitive manual design tasks.

Why CAD, CAE & Mechanical Design Skills Matter for Careers

In 2026, industries are actively hiring engineers skilled in:

- CAD design software for mechanical engineers

- CAE simulation for mechanical design

- Advanced CAD design techniques

- Mechanical CAD design for manufacturing

High-Demand Career Roles

- Mechanical Design Engineer

- CAD Automation Engineer

- CAE Simulation Analyst

- Product Development Engineer

- Digital Manufacturing Specialist

Engineers with expertise in mechanical design with CAD and CAE integration consistently command higher salaries and faster career growth.

Conclusion: The Future of CAD Is Intelligent & Performance-Driven

Generative design and parametric modelling are no longer optional skills—they are core technologies shaping the future of CAD, CAE, and mechanical design in 2026 and beyond. With AI-driven optimization and real-time simulation becoming industry standards, engineers must evolve to stay relevant.

By mastering advanced CAD techniques, parametric CAD modeling, and CAE-driven validation, engineers can build smarter, faster, and more reliable products.